+7 913-923-66-02

+7 913-923-66-02

|

|

Automated lines

The company designs and completes automated factories for polystyrene concrete production.

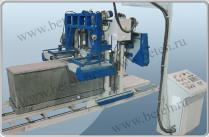

AUTOMATIC CUTTING COMPLEX АRK-004 (2G)

Our company’s professionals have designed the Automated Cutting Machine ARK-004 for aerated, foam or polystyrene concrete blocks and other materials.

Cutting machine for polystyrene concrete

Automated foamed concrete cutting set allows decreasing manual operations and increasing productivity. Cutting set is used for horizontal and vertical cutting of foamed concrete mass into blocks with given sizes. Cutting set ensures cutting at any stage of curing (from the 24-hours till maximum hardness).

DG-1 Crusher

Crusher grindes foamed concrete, aerated concrete, polystyrene concrete and others to size 0-30 mm.

Chemical admixtures batcher

Chemical admixtures batcher is designed for weight dosing of powder-like chemical admixtures during technological process. Dosing quantity is specified by operator.

Aeration system

Equipment set for aeration systems is designed for adjustment, treatment and control of air flow supplied to elements. Set for loosening system is used in different industries.

PND-1000 Polystyrene foaming set

The set is used for foaming polystyrene granules. Foaming is carried out in two stages.

PND-500 polystyrene expanding machine

PND-500 is meant for polystyrene granules expanding in process lines manufacturing polystyrene concrete. Granules’ expanding is performed by thermal treatment using saturated steam.

Granules dryer

Machine is meant for drying and oxygenation of pre-expanded polystyrene granules before entering ageing hopper.

Pneumatic transport

Pneumatic transport is designed for transportation of EPS granules with bulk density from 6 to 50 kg/m3 by air flow between ageing hoppers and process sections.

Ageing hoppers

Ageing hoppers are designed for drying and pressure leveling in polystyrene granules after expanding, and also for granules intermediate storage.

EPS Volumetric batcher

Bather is a hopper made of galvanized steel. It is equipped with volume sensor and gate with air drive. Meant for batching and feed of polystyrene granules.

RS-1000 Mobile Station (with in-built foam generator)

Politern Machine is used for production of foam and polystyrene concrete of various densities.

GN-10 Gerotor pump

GN-10 gerotor pump is meant for pressure transfer of foamed concrete and polystyrene concrete mortars with fibroglass or solid particle up to 5 mm.

GN-20 Gerotor pump

Designed for supplying polystyrene concrete, foamed concrete and also paint and plaster mortars, paste fillers, emulsions and other materials to work place.

Water gauge

DV-1700 batcher of water and liquid components of through type is meant for dosing of different not aggressive and heavy liquids (water, solutions, liquid components and mortars).

Dosing machine for chemical additives DHD

Dosing machine for chemical additives DHD is meant for preparation of chemical additives solutions and volume batching of these solutions in the technological process in quantity specified by operator.

PGES-75 Steam generator

Electrode foam generators PGES-50 (75) are meant for operation together with polystyrene foaming machines. Foam generator is a machine making saturated steam.

PGES-50 Steam generator

Electrode foam generators PGES-50 (75) are meant for operation together with polystyrene foaming machines. Foam generator is a machine making saturated steam.

Molds for polystyrene concrete pouring

First of all molds used for making polystyrene concrete products must provide compliance of products’ shape to GOSTs requirements. For molds production both metal and wood materials (for example, water resistant plywood) are suitable.

Big-Bag Debagger

Debagger is meant for discharge and further transportation of bulk materials from container to the tank, cement truck, weigh hopper, etc. using screw conveyor.

Screw conveyor

Screw conveyor is meant for horizontal and inclined transportation of fines (cement, fly ash). It provides stable feed of materials into process equipment.

Automatic weigh hopper

Hopper is designed for weigh dosing and feeding of inert and binding materials in manual and automatic mode.

Hopper (silo) for cement storage

Silo is a welded tank of cylindrical form with cone bottom. It is structured for intake of fines (cement, fly ash) from cement trucks and their storage.

DP-3 Polystyrene foam Crusher

Machine is designed for expanded polystyrene wastes crushing. Material is crushed between rows of metal hammers installed on shaft. |