+7 913-923-66-02

+7 913-923-66-02

|

|

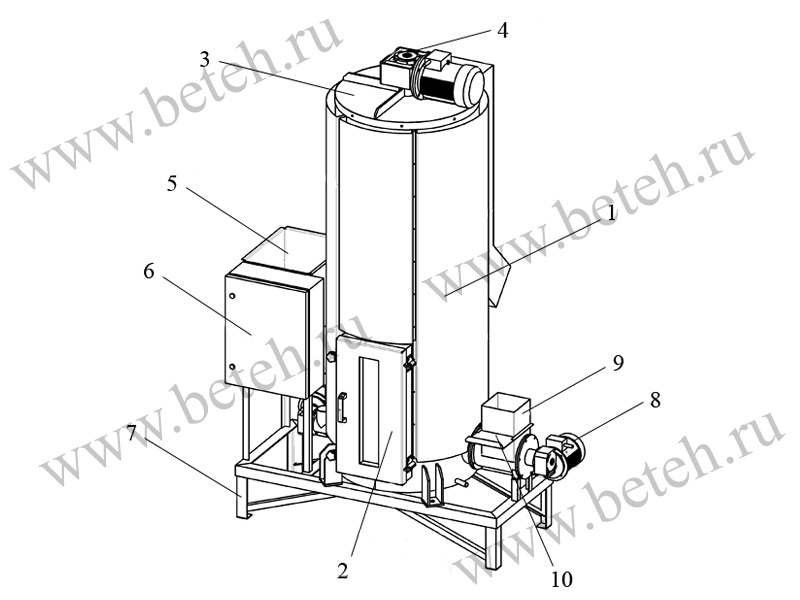

PND-1000 Polystyrene foaming setThe set is intended for foaming polystyrene granules (stainless steel). Foaming is carried out in two stages. The first foaming (bulk density 13-16 kg/m3), then maturing 5-12 hours (depending on the temperature of the workshop, humidity, method of transportation, etc.) and the second foaming. The second foaming serves for obtaining bulk density of granules (AVG) 8-10 kg/m3, depending on the type of raw material. The set is used at facilities having electricity and water for the steam generator (or a centralized steam supply system), at environment temperature not less than 0 oC (273 oK) indoors or under a shed. The set must be connected to a three-phase ac network with 380V and 50Hz frequency, with dead grounded neutral through protective cutout device.

|