+7 913-923-66-02

+7 913-923-66-02

|

|

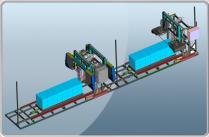

Automated lines - mini plant for aerated concrete production

Modern plant for aerated concrete production is a computerized industrial system guaranteeing high accuracy of components batching and providing quality and competitive products.

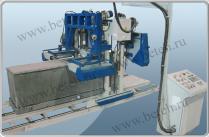

AUTOMATIC CUTTING COMPLEX АRK-004 (2G)

Our company’s professionals have designed the Automated Cutting Machine ARK-004 for aerated, foam or polystyrene concrete blocks and other materials.

ARK Cutting machine for aerated concrete

Automated system which helps you to exclude a lot of manual operations and increase labor efficiency.

DG-1 Crusher

Crusher grindes foamed concrete, aerated concrete, polystyrene concrete and others to size 0-30 mm.

Chemical admixtures batcher

Chemical admixtures batcher is designed for weight dosing of powder-like chemical admixtures during technological process. Dosing quantity is specified by operator.

Aeration system

Equipment set for aeration systems is designed for adjustment, treatment and control of air flow supplied to elements. Set for loosening system is used in different industries.

Water gauge

DV-1700 batcher of water and liquid components of through type is meant for dosing of different not aggressive and heavy liquids (water, solutions, liquid components and mortars).

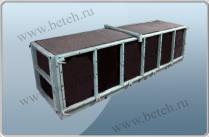

Molds for aerated concrete pouring

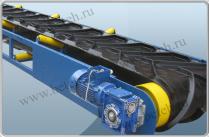

Belt conveyor

Belt conveyor is meant for transportation of bulk materials in horizontal and inclined directions. It is possible to produce belt conveyors of different efficiency and dimensions.

Big-Bag unloading system

Debagger is meant for discharge and further transportation of bulk materials from container to the tank, cement truck, weigh hopper, etc. using screw conveyor.

Screw conveyor

Screw conveyor is meant for horizontal and inclined transportation of fines (cement, fly ash). It provides stable feed of materials into process equipment.

Automatic weigh hopper

Hopper is designed for weigh dosing and feeding of inert and binding materials in manual and automatic mode.

Hopper (silo) for cement storage

Silo is a welded tank of cylindrical form with cone bottom. It is structured for intake of fines (cement, fly ash) from cement trucks and their storage.

Mixer of aerated concrete GB-0,85

GB-0,85 Mixer of aerated concrete is designed for making structural and insulating aerated concrete mixtures of bulk weight 700 – 1000 kg/m3. It is possible to produce structural and insulating aerated concrete of bulk weight 300 – 400 kg/m3. |