+7 913-923-66-02

+7 913-923-66-02

|

|

Equipment set with raw materials manual loading

In addition to automated lines, our company offers complete sets of equipment for small enterprises with manual loading of raw materials.

Line capacity of 10 m3/a shift

We offer you equipment sets with raw materials manual loading. The set consists of:

“RSG-500”, “RSG-1000” foamed concrete mixers. The sets are designed for manufacturing foamed concrete of different density.

The set consists of the following units assembled on one frame:

Mixing device includes two oppositely directed screws which provide quality stirring of mixture components. due to the mixer design there is no need in using any additional pumps for mixture unloading, the mixture is supplied to point of laying by overpressure in the mixer. Compressor.

Reciprocal compressor Aircast is meant for compressed air supply to the system. Compressor AirCast has belt drive and cast iron head LACME.

Vibrocribble for sand sifting.

VG-1 vibrocribble is used for screening sand granules larger than 2 mm. Vibrocribble screens and divides sand into several fractions. RK-3 Cutting machine.

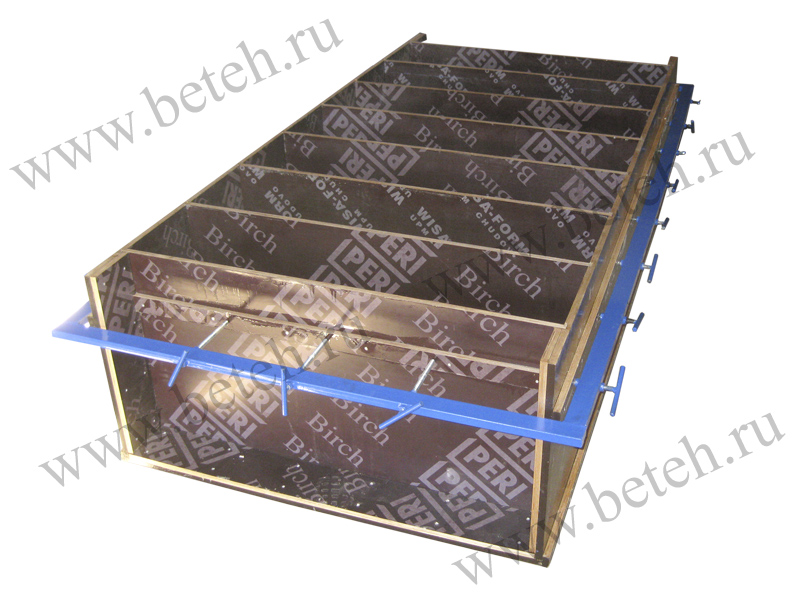

“RK-3” cutting machine is used for sawing foamed concrete, polystyrene concrete or gas concrete into blocks. This technology provides block sizes of high accuracy. When applying cutting technique you avoid a lot of manual operations and increase efficiency. Sawing blocks have sizes with accuracy ±1mm, so laying can be done with using glue and also walls heat efficiency increases significantly. The cutting machine consists of roll table and bandsaw machine which divides mass into blocks. FM-0,84 m3, FM-1,47 m3 Molds

For molding FM-0,84 m3 and FM-1,47 m3 molds are used. Blocks that you get as a result of mass sawing have permanent length and height because these parameters are achieved by mold dimensions. Block width is adjusted during sawing.

Operation principle:

Water, cement, sand and chemical admixtures are loaded in the mixer. Solution is stirred for 4 minutes till it is homogenous. When solution is ready operator turns on foam generator and required quantity of foam enters the mixer. Foamed concrete is stirred for minutes. Ready mixture is unloaded into the molds through overpressure in the mixer. After molding the molds are exposed to thermal treatment. This kind of treatment fastens hardening process before demoulding and also increases foamed concrete strength.

After molds disassembling, mass is put with lifting mechanism on the receiving roll table. Then operator turns on band saw drive. Operator moves the machine module by hands, and cuts off a block of required size. Then the machine module returns in its initial position. Ready blocks are stacked on pallet and wrapped with stretch wrap. Pallets with blocks are stored in finished products warehouse until blocks get 70 % of strength and not more than 25 % of moisture. Temperature of finished products storage should be at least +150 ??.

Advantages:

Purchasing this set you also will get:

- Drawings for independent molds manufacturing;

- Process regulations for foamed concrete products;

- Recommendations for products use;

- GOSTs necessary for production;

- Free training on existing plant;

- Post-warranty service, technologist’s advising;

- Technologist’s visit for set adjustment and compositions selection.

|